Fri 27 Feb 2026 | 19:06 Beijing

TUBE MILLS>

LSAW PIPE MILLS> LSAW Pipe Mill

LSAW Pipe Mill

|

|

|

|

Multi-stroke PIPE MILL has been proved to be the best way to manufacture large diameter longitudinally welded pipes. The plant features with low investment compared with UOE, high efficiency compared with 3-roll bending, low running cost in terms of tooling consumption, high product quality, etc. Our LSAW PIPE PLANT can produce pipes from 16" to 60" in diameter, and 6mm to 65mm in wall thickness, and 8-18m in length.

Edge miller

Crimping machine

Forming Press

Tack welding system

Internal SAW system

External SAW system

Pipe Mechanic Expander

Hydrostatic tester

Pipe end beveling machine

NDT (X-ray, UT, etc.)

Plate and pipe handling system

CADCAECAPPCAM

|

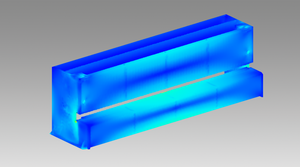

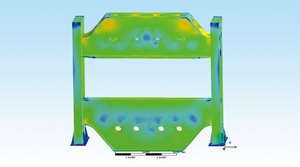

ANSYS (CAE) |

|

Model Simulation

Structure analysis

Optimized design

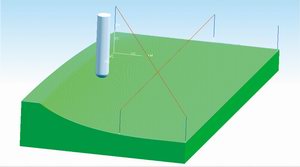

Programming processing

|

|

|

UGS machining (CAM) |

|

Product Full Life Cycle Management (PLM)

|

|

Typical Reference List for LSAW Pipe Mill

|

Year

|

Model

|

Pressure

|

Max. width

|

Bending length

|

Clients

|

|

kN

|

mm

|

mm

|

|||

|

2002

|

PPF5200/125H

|

52000

|

12500

|

12200

|

Qingdao Wuxiao

|

|

2003

|

PPF3600/122

|

36000

|

12200

|

12000

|

Shanghai Yueyuecao

|

|

2004

|

PPF3600/122

|

36000

|

12200

|

12000

|

Hefei Zijin

|

|

2005

|

PPF5200/130

|

52000

|

13000

|

12200

|

Panyu Zhujiang

|

|

2006

|

PPF6000/125

|

60000

|

12500

|

12200

|

SWECOMEX, Mexico

|

|

2007

|

PPF3600/130

|

36000

|

13000

|

12800

|

Wuxi Yulong

|

|

2007

|

PPF5200/138

|

52000

|

13800

|

13500

|

JINDAL SAW, India

|

|

2007

|

PPF3600/125

|

36000

|

12500

|

12200

|

Ningbo Zhehua

|

|

2008

|

PPF5600/132H

|

56000

|

13200

|

13000

|

ESSAR Hazira, India

|

|

2008

|

PPF6500/135

|

65000

|

13500

|

12500

|

Qing Xiang Julong

|

|

2008

|

PPF6500/135H

|

65000

|

13500

|

12500

|

Nanjing Julong

|

|

2009

|

PPF3600/125

|

36000

|

12500

|

12200

|

Hangzhou south-east grid

|

|

2009

|

PPF3600/125

|

36000

|

12500

|

12200

|

Nanjing Daji

|

|

2009

|

PPF5200/130

|

52000

|

13000

|

12200

|

Yangzhou Yalian

|

|

2009

|

PPF5200/130

|

52000

|

13000

|

12200

|

Panyu Zhujiang

|

|

2009

|

PPF6500/135

|

65000

|

13500

|

12500

|

Panyu Zhujiang

|

Please visit the individual page for detail of each machine.