Thu 19 Feb 2026 | 13:24 Beijing

INDUCTION HEATING EQUIPMT>

INDUCTION HEATING EQUIPMENT> Solid State Induction Heating

Solid State Induction Heating

I. Solid State Induction Heating Equipment

The solid state induction heating system integrates the modern power electronic device MOSFET / IGBT module as the power source of the inverter. The intellectualized control system based on single chip microprocessor of the rectifying and inverting features with high efficiency, simple and reliable circuit, easy commissioning and operation, energy saving, high product quality, etc.

They are widely used in welding, melting and refining, quenching and tempering, annealing, brazing and soldering, sintering, holding and pouring systems for metal and material processing including steel, iron, aluminum, copper, brass, zinc, precious metals, silicon and graphite, etc.

|

|

|

Bar Annealing |

Corner Annealing |

|

|

|

HF H-Beam Welidng |

MF Seam Annealing |

|

|

|

|

|

|

|

HF Tube Welding |

HF/MF Quenching |

1. GCYP/GZP Series Super Audio / M. F. Induction Heating Equipment

This type of induction heating equipment has the IGBT (Insulated gate bipolar transistor) module as the key component to form a parallel inverter, and convert the three phase alternating current of 50Hz/60Hz line frequency to the single phase AC super audio / M. F. power supply.

Frequency: 1 kHz-50 kHz

The GZP series IGBT medium frequency induction generator is a high frequency power supply that It is applicable mainly in smelting and refining, hardening and tempering, annealing, brazing and soldering, etc.

2. GGP Series H. F. Induction Heating Equipment

This type of induction heating equipment has the MOSFET (Metal oxide semiconductor field effect transistor) module as the key component to form a serial inverter, and thus transforms 3-phase line frequency (50Hz) AC power into single-phase AC H. F. power supply.

Power: 10kW-400kW

Frequency: 50 kHz-500 kHz

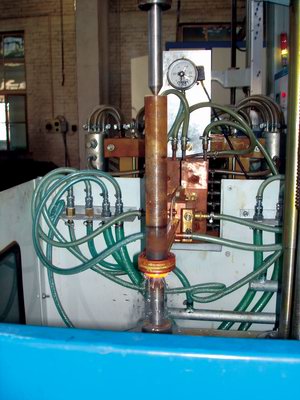

3. KGPS Series Thyristor M. F. Induction Heating Equipment

In KGPS series thyristor (SCR / Silicon controlled rectifier) induction heating equipment, the 3-phase line frequency (50Hz) AC power is firstly transformed into DC power by a 3-phase bridge type rectifying circuit, and then inverted, after filtering (DC reactor), into single-phase M. F. power by a parallel inverter. With 89C51 SCM as the core of control, and peripheral VLSI (Very large scale integration) circuit, the equipment makes the best use of the computer’s strong software and hardware functions and achieves optimum regulation of rectifying and inverting.

Power: 50kW~1500kW

Frequency: 500Hz~8 kHz

II. KGS Series High Power DC Power Supply Cabinet

KGS series high power DC power supply has the thyristor as a key part of the 3-phase voltage regulator. With SCM as the core, it forms a intellectual control system capable of voltage regulation and rectification. The PLC enables accurate control of heating temperature, heating power, stand-by time and cooling time so as to ensure the heating technology, and the HMI (touch screen type) facilitates setting of these parameters. The whole system enjoys the merits of high efficiency, simple and reliable circuit, and easy operation and testing. This improved technique helps the manufacture save significant power and also further improve the product quality.

Output DC voltage: 6V-440V

Output DC current: 100A-12,000A

III. CNC & PLC Quenching System

1. CNC Quenching System

The CNC quenching system is a complete set of equipment featuring high-precision and high-efficiency control. It integrates quenching machine, computer, driver, motor, and the technique of auto-control, auto-detection, and auto-analysis. It basically consists of processing program, CNC system, servo system, auxiliary control equipment, feedback system and the quenching machine.

The application of CNC system greatly improves the precision of the machine’s operating movement as well as the precision of controlling, thus the whole dynamic performance. Its quenching program is in international standard language and very easy to learn, which facilitates parameter resetting of the operator.

2. PLC Quenching System

The PLC system enjoys universality, good flexibility and high reliability. The program is simple and easy to learn. The operator can easily change the parameter setting to meet requirements of different work pieces.

IV. Water Cooling System

The water-water cooling system adopts a plate type heat exchanger of special corrugated structure, where the soft water is formed into turbulent flows at a low speed, thus the heat exchanging effect is strengthened. The whole design allows small space occupied, easy assembly/disassembly, and high exchanging efficiency. The cooling water is recycled water supplied from out of this cooling system, so continuous cooling is possible.